I wanted to create a water bottle that a) holds a decent volume of water (0.5l) and b) fits into a specific location that is convenient for me when walking my dogs (needed to be flat’ish). And, this is what I came up with – essentially a large flask. But what I learned is even more interesting than the product itself. Most of what I learned is about leaking. However, I incorrectly assumed that sealing the cap to the bottle would be my biggest challenge. But it wasn’t.

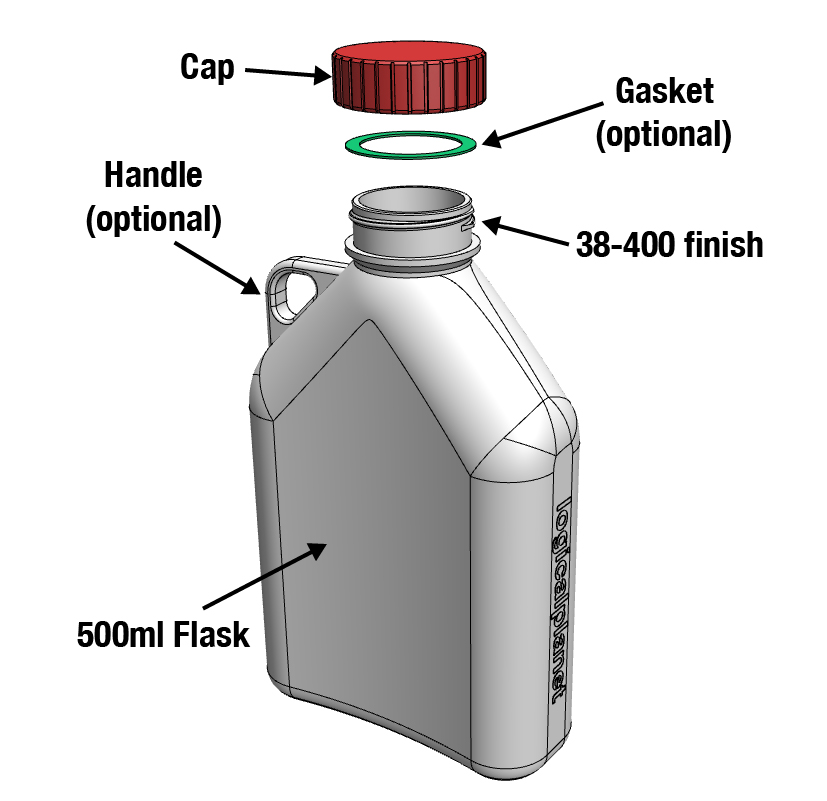

But I started with the issue of cap and thread so I will discuss that first… The “finish” – apparently that is what the thread and cap combination of bottles/containers is called – was the first challenge to sort out. I wanted to use something fairly standard but I wanted it larger than the average water/soda bottle. After some research, I decided to use the 38-400 “finish”. Most soda/water bottles use a 28-400 finish. This means the inside of the cap (the outer dimensions of the outer threads are about 28mm. And, the 400 indicates 1 turn of the thread. The 38-400 I chose to use is similar but with a 38mm diameter of the outermost thread (inside the cap). And, because I anticipated it being difficult to seal I designed the cap with a space for the TPU seal (or gasket) similar to what we often find inside soda bottle aluminum caps – a small thin flexible seal to close the gap between the top of the bottle and the cap.

But, after some testing, I found that the cap-to-bottle seal without the gasket was already very good. By filling the bottle with water, closing the cap tightly and then squeezing the bottle I could quickly test the effectiveness of the cap. And, it did not leak.

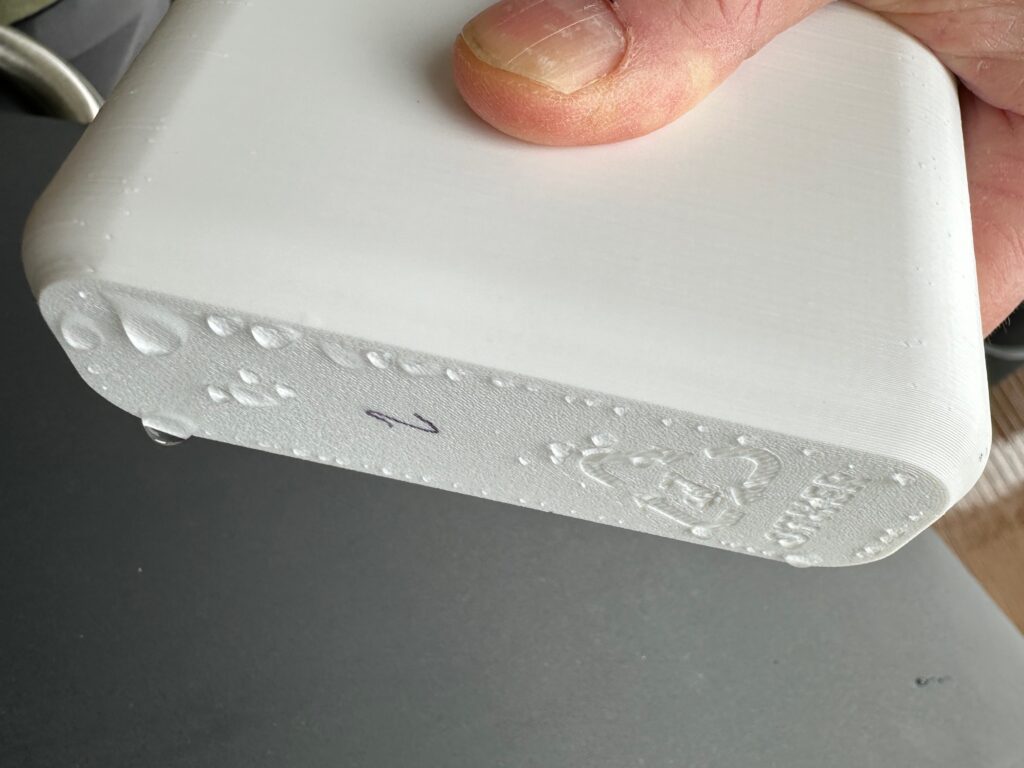

However, what I did discover was that water permeated out through the material (PETG) of the bottle. It was most noticeable on the bottom of the bottle. I found this very strange as I was at that point using a 0.4mm nozzle to create 1.6mm walls (i.e. solid walls) and the bottom was 1.6mm thick printed with a 0.2mm layer height (therefore 8 layers of print).

Making matters more curious I added a recycling identifier to the bottom of the bottle and inset that 0.2mm. So at that point, the bottom was only 1.4mm and it was not leaking there. It appeared to be leaking around the perimeter of the bottom but not at the very edges, perhaps inset about 3 or 4mm.

Since the leaking seemed to be specifically related to the bottom perimeter, I decided to increase the internal chamfering radius to drop more material in the bottom. I also increased the bottom to 2.4mm in thickness. And, lastly made sure I was printing with 100% infill.

The results were good. Very good. I could then pressurize the bottle and there was no more leaking from the bottom (or the cap). But now I could see there was a very small amount of water permeating out of the walls. It was so little I did not initially notice it.

So I increased the wall thickness to 2.0mm and I now seem to have a completely sealed vessel which I will use for a while and see how it performs. Since this was enough of a lesson and time spent on something I did not really need I decided to stop here. But my conclusion is that if I really needed to print a sealed vessel I would probably increase the wall thickness even more to 2.4mm or more. AND, I would spend some more time experimenting with print settings to see if I could improve the density of the walls; perhaps through over-extruding or overlapping lines.

I know the idea of printing a bottle does not make much sense, but it has some novelty and possible applications, especially when a single custom-size or custom-shaped vessel is needed. I also think it might be interesting to try to print a cylinder for compressed air and try to 3d print a miniature pneumatic system. Definitely for future fun but I will keep that on the list of things to do.

Printing

I have tried to make the print orientation and my main print settings visible on the Cura screenshot(s) but in case they are difficult to read I have summarized them again here…

Material: I choose to use PETG for its durability and flexibility.

My Setup:

Nozzle = 0.4mm

My Settings:

Layer height = 0.2mm

Line width = 0.4mm

Wall count = 4 (1.6mm)

Infill = 100%

Support:

Designed to print without support.

Print Orientation: As shown in the screenshot(s).

Leave a Reply